From Screen to Sculpture: Making things the Blott Works way

Every Blott Works piece is an exercise in engineering and craftsmanship, moving from digital precision to hand-finished detail. Here is how they come to life:

1. Design & Prototype Most things begin with an interaction idea. There is usually a bit of playful prototyping in the workshop, before the mechanics and aesthetics are modelled in 3D CAD software to ensure the proportions and movements are perfect before a single piece of material is cut.

2. Metalwork

The Skeleton: 2D shapes are exported and laser-cut from aluminium sheet. Once back in the workshop, these are cleaned up and sent off for 'hard' anodising to create a durable and beautiful gun-metal grey surface.

The Details: Round aluminium and brass components are turned by hand on a vintage 1960s metal lathe.

3. Woodwork

Shaping: Timber parts are cut, drilled, and shaped using bandsaws, press drills, and routers. Some elements are turned on a lathe or shaped entirely by hand.

Forming: For the curved rockers on the Balance lamps, layers of birch ply and hardwood veneer are cold-formed in a vacuum press.

4. The Finish This is where the tactile quality comes in. Metal and wood parts are sanded and polished to a smooth satin finish.

Wood: Treated with a specialist oil to bring out the grain.

Metal: Sealed with a museum-grade silicon wax for protection and a subtle sheen.

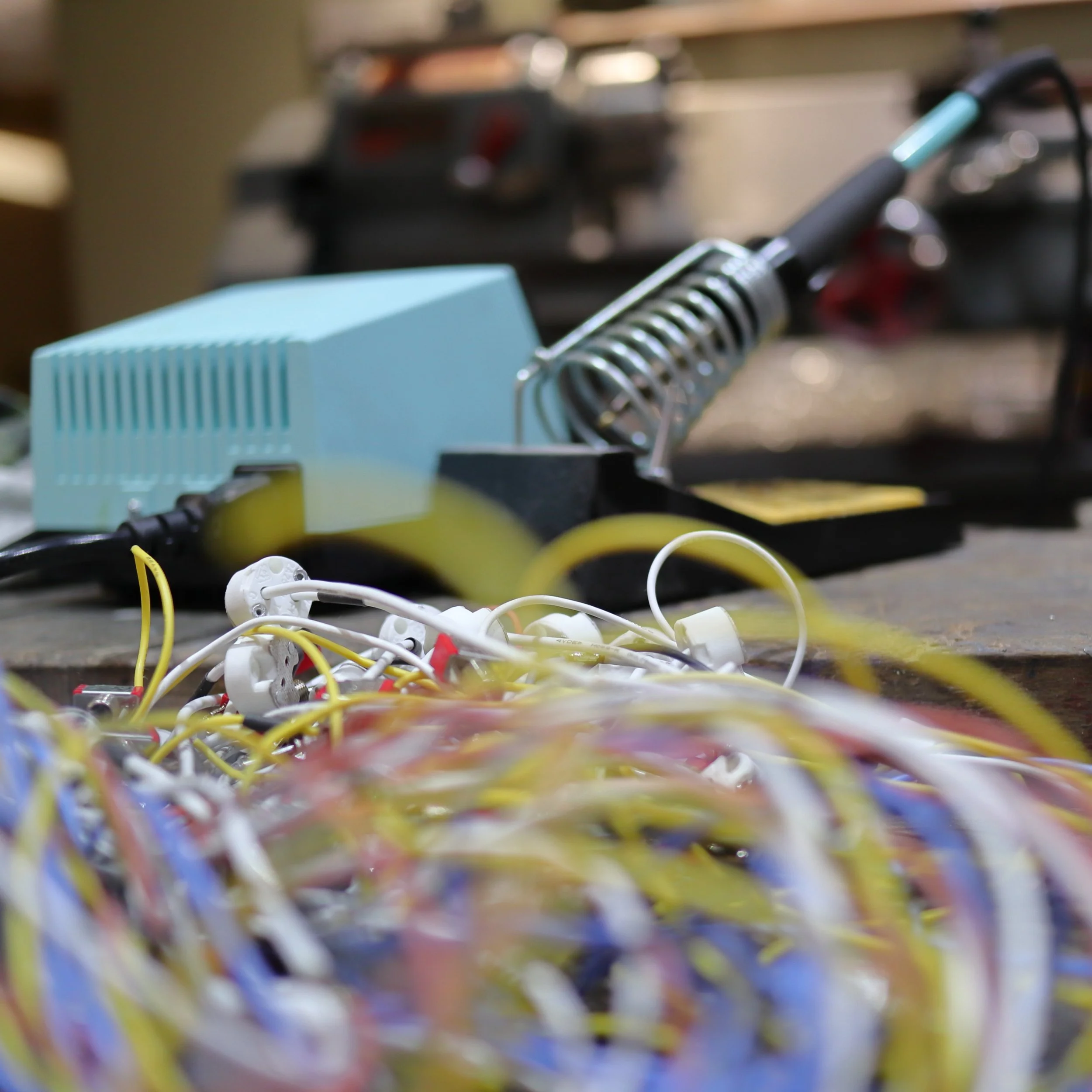

5. Assembly Finally, the mechanical parts are bolted together, and the electrical elements are soldered and fitted, transforming a collection of parts into a functional sculpture.